|

QingDao DeerMa Plastic Machinery Co., Ltd.

|

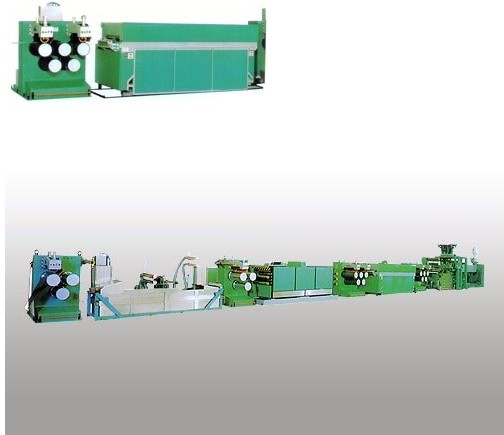

PP strap band production line/PP strap band making unit

| Payment Terms: | T/T,L/C |

| Special Groups: |

PP strap extrusion line (3)

|

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

PP strap production line with high quality,this line used 100%recycle material,is characterized with compact structure,ease operation,the huge output.

PP strap band production line description:

This PP strap band production line applies automatic feeding and drying facility .The screw and barrel of extruder are made of 38CRMOAIA.The extruder head could be lift and while the die mouth gap is adjustable. This is useful to change product size withoutshut down. The inverter speed control is used in extrusion, drawing and stretching. The whole system consists of seven unit such as extruder, stainless steel cooling sizing water tank, stretching sizing control panel, stainless steel heating water tank, stretching sizing control panel, stretching-printing-embossing calender and two-position wider. Twin drawing technology is used in all drawing to optimize the flatness of package tape with clear pattern. The winder applies internationally advanced linear structure device to meet various sizes of product. PP is used as major raw material. The technical parameters are better than those of competitors in the market.

This PP strap band production line applies automatic feeding and drying facility .The screw and barrel of extruder are made of 38CRMOAIA.The extruder head could be lift and while the die mouth gap is adjustable. This is useful to change product size withoutshut down. The inverter speed control is used in extrusion, drawing and stretching. The whole system consists of seven unit such as extruder, stainless steel cooling sizing water tank, stretching sizing control panel, stainless steel heating water tank, stretching sizing control panel, stretching-printing-embossing calender and two-position wider. Twin drawing technology is used in all drawing to optimize the flatness of package tape with clear pattern. The winder applies internationally advanced linear structure device to meet various sizes of product. PP is used as major raw material. The technical parameters are better than those of competitors in the market.

The main technique parameter of PP strap band production line:

Band width: | 9-32mm |

Production linear speed: | 120m/min |

Stretch ratio: | 4-9 |

Max.output | 60-200kg/h |

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!